Sandblasting & Industrial Painting Specialists

If you need any sandblasting or industrial painting carried out at your premises, Direct Blast are the company to trust.

Direct Blast can provide you with many different services like:

- Abrasive blasting

- Applying protective coatings

- Industrial spray painting

We have the latest equipment, modern facilities that include paint booths, one 20x6x5 metres and the other 10x6x5 metres. Our specialist operatives use custom-built blasting booths and heated spray booths so they can work 24 hours a day if needed. Other services we offer are:

- Sandblasting

- Mobile sandblasting

- Soda blasting

- Dustless blasting

- Crack testing

Useful Protective Coating Reports

Should you require specific protective coating reports, we can help. Our reports adhere to many different standards as well as Australian Standards. A highly qualified NACE inspector makes sure all specifications are followed precisely and can provide comprehensive paint or coating reports along with:

- Blast profiles

- Temp/humidity/dewpoint reports

- Spark testing and continuity

- Dry film thickness reports

- Adhesion and chloride testing

Nothing is too much trouble for our inspector or workforce. If you need any sandblasting, abrasive blasting or industrial painting jobs doing, no worries.

Why Have Protective Coatings?

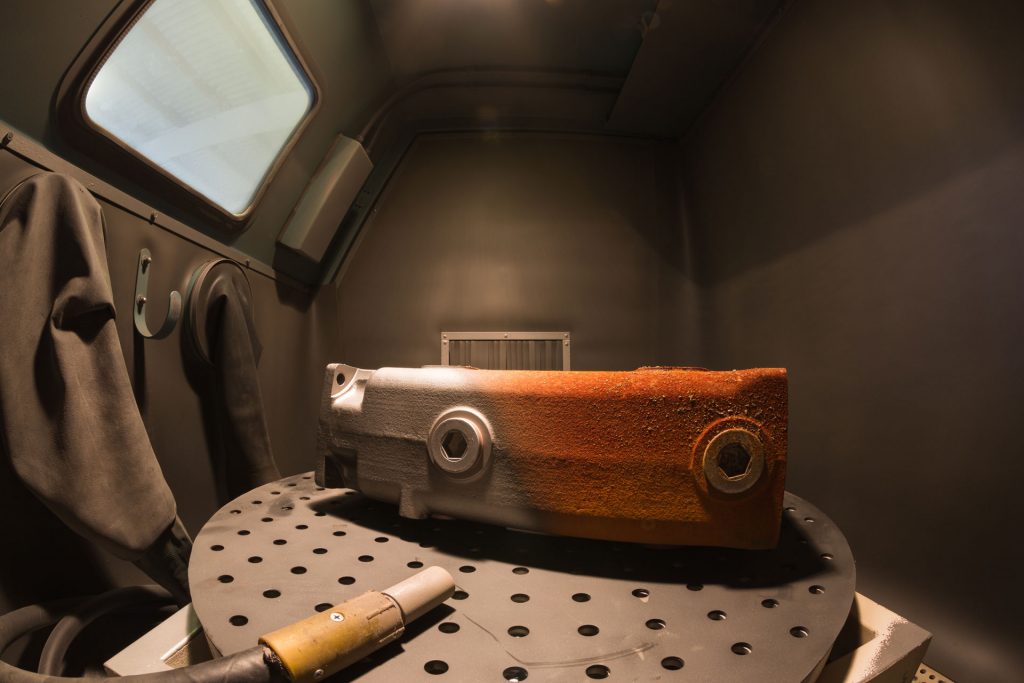

The main reason to have protective coatings is to protect surfaces from fire or corrosion. Coatings available include:

- Epoxy primers

- Polyurethanes

- Zinc

- Silicone

All of the above are hard-wearing, durable and will certainly improve the look of the surface. Mining and transport equipment can also be painted or coated without any problem. With years of experience behind us, we know how to provide industry grade services whether it’s for protective coatings, industrial painting or sandblasting.

A Perfect Finish Guaranteed

Expect a perfect finish for any painting or blasting job. Abrasive blasting is perfect for cleaning or etching a surface. It makes it easy to apply paint or other kinds of coatings. Using high pressure tools and steel grit, results in a smooth finish while chilled iron grit and garnet blasting can be used for any size job. Soda blasting on the other hand is a good alternative to traditional sandblasting. Bicarbonate of soda, which is used in this type of blasting, won’t damage surfaces and is used for:

- Removing paint from wood, bitumen, glass and concrete

- Degreasing engines

- Stripping paint from car bodies

- Cleaning brickwork to get it back to its original colour

If you’re not sure of which kind of sandblasting is most suitable for a particular job, make contact with our staff who will be more than happy to help you out.